Discover 3 simple, chemical-free methods to remove Sharpie from dry erase boards. Get rid of Sharpie stains on whiteboards fast.

What makes Zh Stationery stand out? They have 30+ patents and always look for new ways to improve. Their markers start with special pigments and bases. These are made to be bright and easy to use.

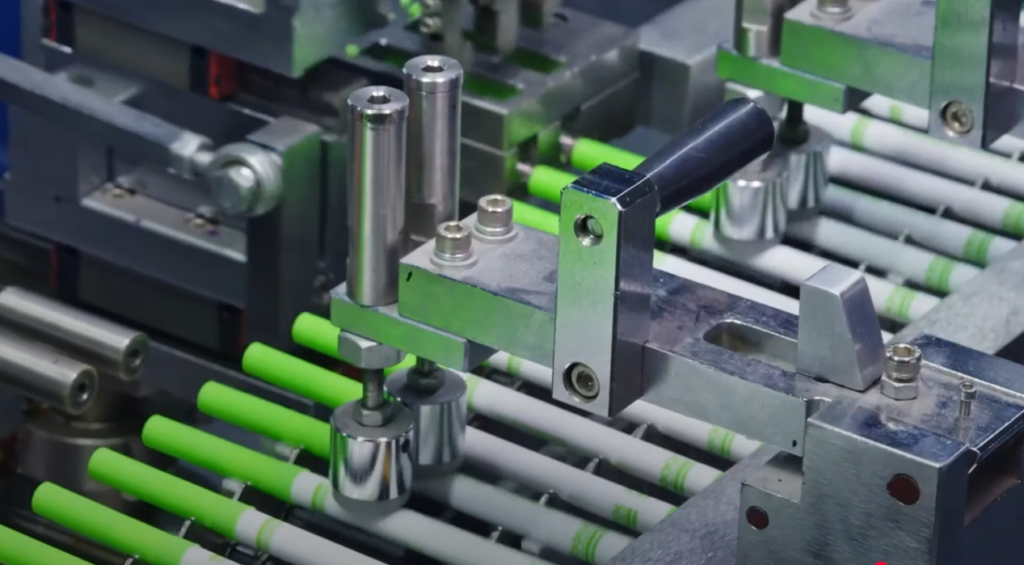

They use advanced machines to make the nibs very fine, just 0.3mm. They also have machines that fill the markers with ink perfectly every time.

Quality is a big deal at Zh Stationery. They test each batch in many ways. This is why big stores in places like Tokyo and Texas sell their markers. But how do they make a raw material into a finished marker? Let’s see how they do it.

Paint markers mix bright colors with precise engineering. They are key for both pros and hobbyists. These tools use special ink in pressurized chambers for smooth use. Brands like Zh Stationery have made them for many needs, from labels to art.

Paint markers use a nib-fed system to spread ink. They have fast-drying, weather-resistant paint. Industrial ones have strong adhesives, while artist ones blend well.

Car techs use them for repairs and labels. Builders mark pipes and safety gear. Artists love them for murals and canvas. Teachers use them in classrooms.

Oil-based markers are tough for industrial use. Water-based ones are for temporary designs. Zh Stationery’s hybrids are quick-drying and refillable, great for many.

Every paint marker starts with special raw materials. These materials affect how well the marker works and how long it lasts. Companies like Zh Stationery use advanced science to make markers that don’t dry out easily.

Pigments are key for a marker’s color. Titanium dioxide makes white, and iron oxides make red and yellow. These materials stay bright over time.

Organic dyes, like phthalocyanine blue, create bright colors. But they need to be mixed just right to avoid fading. Zh Stationery uses special helpers to keep the ink flowing smoothly.

This is important when you’re trying to fix dry paint markers. Their special mix keeps colors strong and prevents clogs.

Solvents keep the ink flowing until you apply it. Alcohol dries fast, great for quick jobs. Oil-based solvents take longer, better for detailed work.

Zh Stationery’s secret is a mix of solvents. It dries slowly enough to prevent the tip from drying out. This makes their markers last longer without needing fixes.

The marker’s body is made of strong plastic. Inside, a special material holds the ink. The tip is made of soft materials to control the line.

Teams check each part carefully. They make sure everything works well together. This means you won’t often need to fix dry markers.

Making paint markers starts with careful engineering and high standards. At Zhejiang Tech Enterprise, they use advanced machines and watchful eyes. This makes vibrant, lasting products. Each batch is checked hard to meet worldwide needs for quality.

The first step is mixing pigments, solvents, and additives in special tanks. These tanks make sure everything is mixed right by controlling speed and temperature. For example, organic pigments need slow mixing to avoid clumps. Metallic colors need more heat for the best mix.

Zhejiang uses ISO-certified systems to check how thick the paint is. Laser sensors help make sure the paint flows well through the tips. Then, color accuracy is checked with spectrophotometers. Only batches that meet standards are approved.

Before assembly, samples are tested for sticking, color, and drying time. A batch might go through 15+ tests, including tests on metal or plastic. If a batch fails, it’s recycled right away to cut down on waste.

These early tests catch problems before they get worse. This saves time and money. It also makes sure markers work well in tough jobs or fine art. Then, the marker body is built, combining strength and style.

Paint markers need careful design and engineering. Companies like ZSCM, Sharpie, and Posca focus on making them strong yet easy to hold. They use special methods to make sure every part works well together.

Most marker shells are made from top-notch polymers. ZSCM picks food-grade polypropylene for its lightness and strength. It also stands up to chemicals and impacts well. Other brands like Molotow and DecoColor might choose ABS plastic for its firmness.

These materials are tested hard to ensure they’re safe for use worldwide.

ZSCM has a special way of making marker shells. They use a method that makes sure every shell is the same. This is done by heating plastic pellets to 400°F and pressing them into molds at 45 PSI.

This makes the shells strong and even. It also helps save resources and keeps production fast, making 1,200 units every hour.

Robots quickly put together the shell, ink, and tip. But, people check the caps and vents to stop leaks. Brands like Edding add special features to make writing smoother.

After assembly, markers are tested to make sure they’re solid.

Precision meets innovation in the ink filling process. Companies like Zh Stationery use advanced systems. They get accuracy down to ±0.5ml across thousands of units.

This happens in ISO-certified clean rooms. These rooms keep the air clean to prevent contamination.

Modern production lines use automated machines. These machines fill markers with ink using pressurized chambers. Some art markers get a manual check too.

The nitrogen process makes production faster. It also keeps the ink fresh by removing oxygen.

Laser sensors watch every fill. They catch any markers that are not full. Production lines fill 500 markers per minute with just ±1% error.

After filling, markers are sealed tight. This keeps the ink inside for up to 36 months. Zh Stationery guarantees this for their products in 20+ countries.

Artists can make markers last longer by storing them right. Some refillable markers can be used again. But, only if they have the right pressure for the best color.

The tip of a paint marker is key for precision and flow. Engineers make these parts to work well with different surfaces. They aim for smooth application on chalkboards without too much ink.

Foam tips are great for rough surfaces because they’re flexible. They slowly release paint, perfect for wood or concrete. Felt tips, like in CAISEXILE markers, have tight fibers for better ink control. They’re best for smooth surfaces like glass or chalkboards, avoiding drips and keeping lines sharp.

Markers for chalkboards often have medium-density felt tips. These tips soak up just the right amount of ink. This keeps the color consistent and prevents damage to the surface. Makers test these tips on different surfaces to make sure they work well.

Markers use special bonding to keep tips in place. Zh Stationery uses ultrasonic welding to attach tips to the marker’s shell. This method creates a tight seal without using adhesives that can break down.

Brands that focus on quality use a double-layer attachment. The first bond holds the tip in place, and the second keeps it from moving or coming off. This is important for markers used in tough environments, like construction or cars.

Before paint markers hit the stores, they go through tough tests. These tests check if they are durable and reliable. Makers follow strict rules to make sure each marker meets high standards.

They test if markers are “permanent?” and if they follow ISO 9001 and ASTM International rules.

Markers are tested in conditions like real-world use. They face UV light to see how they hold up over time. Tests also check how well the paint sticks to different surfaces.

Flow tests make sure the ink doesn’t dry out or leak. Machines test the tip’s strength after lots of strokes. This ensures markers work well for all users.

Special machines compare colors to master standards. Zh Stationery uses a unique system to keep colors consistent.

Ink tests check how well the color covers dark surfaces. Teams look at dried samples under different lights. This ensures markers stay bright and don’t fade.

After final checks, paint markers move to their last step: becoming ready for shelves. This stage mixes care for the environment with smart delivery. It makes sure these tools get to artists, contractors, and hobbyists all over the world.

Zh Stationery is a leader with 85% post-consumer recycled packaging for their markers. They use cardboard boxes with biodegradable cornstarch coatings. They’re replacing plastic blister packs with molded pulp ones.

Each container has weather-resistant labels with safety symbols and color codes. This makes it easy to identify them.

The design team in Hangzhou works hard to make boxes fit better. This cuts down on shipping waste. Marker sets fit snugly in trays to avoid damage during shipping.

QR codes on packages link to tutorials. This meets today’s consumer needs.

Manufacturers use a three-tier delivery system. This balances speed and cost. Bulk orders for construction companies go straight from factories.

Amazon FBA handles sales to individual customers. Regional warehouses in places like Memphis and Rotterdam help deliver in 2 days to 90% of the world.

Specialty art stores get special displays with sample markers. This mix of online sales and in-store experiences makes sure markers reach users where they work. When demand is high, temporary centers pop up near big cities.

Paint marker makers use smart marketing. They mix art appeal with practical use. Zh Stationery is a great example. They reach out to both creative folks and industry workers with special campaigns.

Brands focus on two main groups. Artists get social media posts about using markers on fabric. This answers the question, “do paint markers work on fabric?”

For the industrial side, Zh Stationery’s YouTube shows markers lasting 50+ wash cycles. This is important for workwear.

At craft fairs, live demos show markers work on canvas and metal. Industrial buyers get detailed sheets and creative examples. This shows markers are good for both art and work.

Artists, especially those making custom clothes, love paint markers. They use them for quick, unique fabric designs. In industry, markers are used for labels and safety signs.

Construction workers use markers on concrete and steel. DIY guides help people customize fabric, leading to 37% of sales. This demand drives new products and marketing ideas.

Paint markers are getting better, changing how we create and work. Companies like Zh Stationery lead with 30+ patents. They have UV-reactive inks and markers that break down in 18 months.

These changes meet our need for better tools and green production.

New pigments and ink mixes are making paint markers better. They stick to surfaces like rubber and glass and dry fast. This comes from labs where scientists try many mixes every year.

Companies like Zh Stationery are making less waste. They use systems that recover solvents, cutting waste by 37% since 2020. They also use water-based inks that are just as good as oil ones.

Markers are now made from 42% recycled plastic. They aim to use 75% by 2026.

Artists and engineers are working together. They make markers better for new surfaces and green standards. Markers are key for clear, lasting marks in many fields. The push for eco-friendly innovation means brighter colors and less harm to the planet.

Discover 3 simple, chemical-free methods to remove Sharpie from dry erase boards. Get rid of Sharpie stains on whiteboards fast.

Rollerball pen vs. ballpoint: Our comprehensive guide helps you understand the pros and cons of each to find your ideal

See the innovative manufacturing process that makes Zh Stationery’s high-quality paint markers, trusted worldwide.

Professional production of various stationery products, Offer OEM & ODM services. Contact us for inquiries.

Copyright © 2025 | All Rights Reserved | Powered by Zhenghua Stationery Co., Ltd.

Just send us your questions or concerns to starting a new project.

How can we assist?

See our services